Advantages of aquatic expanded feed

Aquaculture has always been an important part of national agriculture. It depends on mountains and rivers. For the majority of farmers close to the water area, aquaculture fish and shrimp is a realistic and feasible method and way for them to obtain economic benefits. The types of fish feed have also experienced the process from raw to cooked, from shallow processing to deep processing, from the original crushing and direct feeding of fish and shrimp, to the later mature particle feeding, to the current scientific feeding of nutritional ratio. In the whole process of feed evolution, fishermen have deeply realized the importance of feed particle absorption for aquaculture, because the same fish species are fed with different feeds, the time of fish and shrimp entering the market will be very different, and the taste of fish meat is very different, so the economic benefits to fishermen are completely different. Therefore, at present, the types of feed commonly accepted by fishermen are: high protein expanded feed particles, high protein content, fast growth of fish, good absorption, low waste of feed, and less damage to water quality caused by fish excretion, which can be recycled and developed ecological agriculture. It is a powerful tool and means for sustainable fishery development.

Aquatic Expanded Feed

According to different processing technology, aquatic feed products are mainly divided into powder material, granular material (traditional hard granular material) and expanded material

1. Comparison of aquatic feed processing technology:

The processing requirements of expanded materials are more complex than those of granular materials. The main differences are in the processes of conditioning, expansion and liquid spraying:

(1) Conditioning: in the process of conditioning, water and steam are added together to produce expanded materials, and the moisture content after conditioning is about 25%, while only steam is added to produce granular materials, and the moisture content after conditioning is low, about 17%.

(2) Expansion and liquid spraying: there is no expansion process and liquid external spraying process in the production of granular materials, but more granulation process. The processing technology of expanded material requires that the raw materials are crushed more finely. Through the high-temperature expansion process, the maturity of starch can be improved, which is conducive to the digestion and absorption of feed by fish.

(3) Advantages of expanded material: expanded material requires finer crushing of raw materials and high temperature in the processing process, which not only improves the ripening degree of starch, but also strong kneading at the moment of high temperature, high humidity and heat in the expansion process can kill some harmful bacteria in the raw materials. Therefore, compared with ordinary granular material, expanded material can improve the digestion and utilization rate of feed and reduce the incidence of disease.

On the other hand, the expanded material has a stability of 12-36 hours in water, which is convenient to visually check the feeding situation of fish and reduce water pollution.

2. Expanded material and granular material

With the enhancement of the concept of environmental protection and green and healthy breeding, granular materials will be gradually replaced by expanded materials. Compared with powdered and granular materials, although the price of expanded materials is higher, the feed conversion rate is higher, the comprehensive benefit is better, and the pollution to the water area is less. In recent years, the acceptance of expanded materials by farmers has gradually increased.

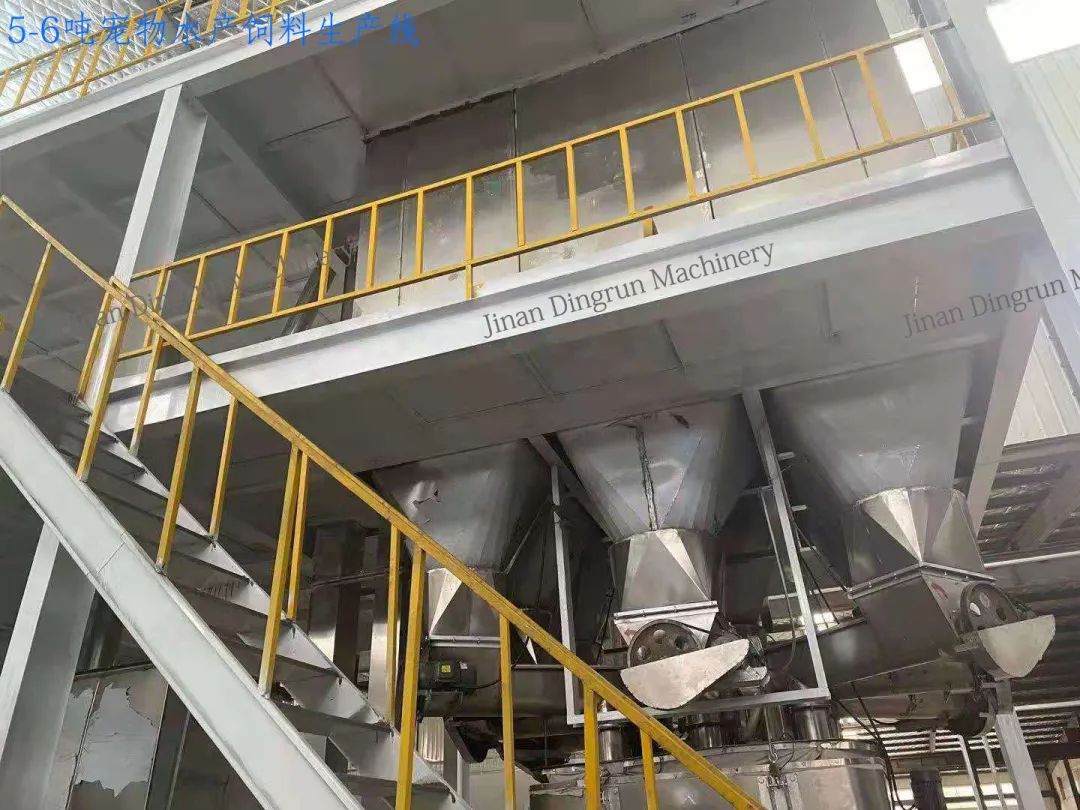

3. Automatic production line

Company :

Jinan Bright Machinery CO.,LTDAddress :

Wande Industrial Park, Changqing District, Jinan City , Shandong Province, ChinaPhone :

+86-15216413153Email :

info@brtbrightmachine.comSkype :

+86-15216413153Whatapp/Wechat:

+86-15216413153