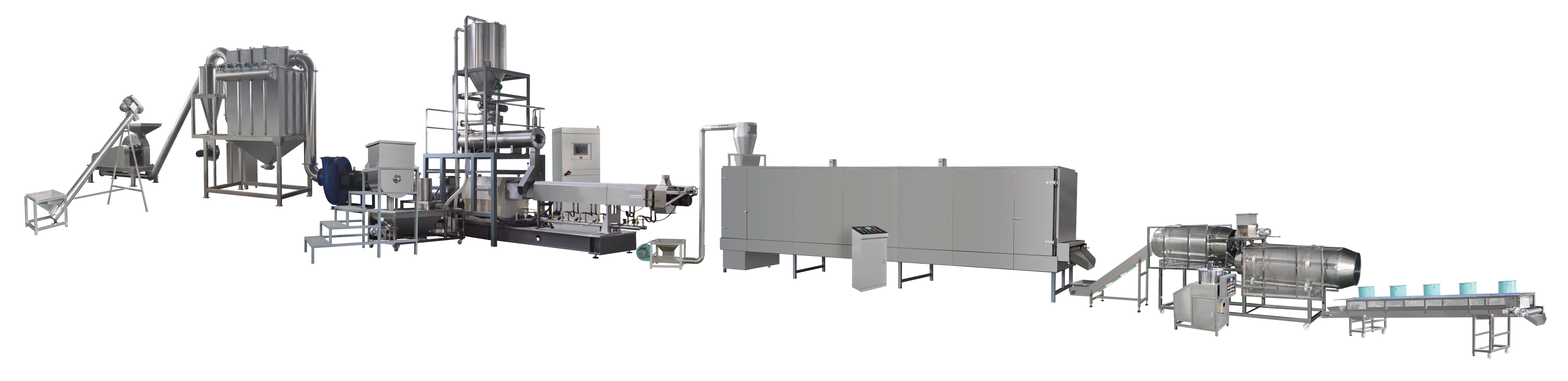

twin screws extruder

Firstly, taking the production of aquatic feed as an example, we distinguish single screw extruder and twin-screw extruder structurally according to the expanded materials and purposes,

Generally:

- single screw extruder: suitable for processing all kinds of raw materials and common livestock and poultry compound feed

- twin screw extruder: the final product requires good molding and beautiful appearance, uniform maturity and adjustable density of compound feed (aquatic feed

Pet food) and high value-added raw materials( ɑ Starch, tissue protein, etc It should be noted that the above division is not absolute. For example, we build

It is proposed to use twin-screw to produce aquatic feed, but at present, many enterprises use single screw to produce aquatic feed. Many articles have introduced their application in aquatic products

In short, compared with single screw, twin screw has the following advantages:

- high yield, up to 98% or higher.

- the particles are well formed and uniform in shape. Twin screw die pressure is very stable to ensure consistent particle forming.

- the unique strong pumping capacity of twin-screw ensures no reverse injection and blockage. After strong quenching and tempering, the steam content in the material is high, and the single screw is in

The feeding area is prone to steam overflow and reverse injection, resulting in unstable material flow and blocking of the machine, while the twin-screw will not have a similar situation.

- it can continuously and stably produce various small particle products. When producing particles with diameter of 2mm and below, the working condition of single screw is unstable and the yield will increase sharply

The material type will become worse when the material is reduced.

- density control is more stable and reliable. The materials melt more fully and evenly in the twin-screw barrel, which can accurately control the production of floating materials and submerged water

Materials and slow settling products.

- wide adaptability to formula and more suitable for high-energy formula production. Twin screw can produce 11 ~ 13% fat (up to 17% according to foreign data)

High energy formula, while the single screw generally does not exceed 6 ~ 8%.

- easy operation and stable production process.

Rod extruder. Of course, the investment and production cost of twin-screw are much higher than that of single screw, which should be considered according to the actual situation.

Company :

Address :

Phone :

Email :

Skype :

Whatapp/Wechat: