artificial fortified rice production line

- +8618753110771

- TT , LC

- 100 sets

a. Raw Materials: adopts corn flour, rice powder as raw materials.

b. Products: different shapes are made by adjusting the dies from extruder

c. Capacity: 200kg/h, 350kg/h, 500kg/h, 1ton/h, 2ton/h

d. Flow chart: Mixing system---Extrusion system---Drying system---Flavoring system---Packing system

artificial fortified rice making plant nutrition rice making machine extruder production line

1.Product Description

The artificial rice processing machine adopts the broken rice, corn, millet, wheat, oats, buckwheat, bean, starch as main ingredient, and some other vitamin and mineral as part of ingredient.The material is extruded into rice shape by the twinscrew extruder, and dried in a rotary dryer to needed moisture content. Artificial rice machine extruding technique makes it possible to strengthen and solidify the micronutrient in the rice. This artificial rice can be mixed with natural rice prior to cooking as usual. When cooking is finished, its grains are not broken and there is no difference between the artificial rice and the natural one in viscosity, elasticity and taste.

a. Raw Materials: adopts corn flour, rice powder as raw materials.

b. Products: different shapes are made by adjusting the dies from extruder

c. Capacity: 200kg/h, 350kg/h, 500kg/h, 1ton/h, 2ton/h

d. Flow chart: Mixing system---Extrusion system---Drying system---Flavoring system---Packing system

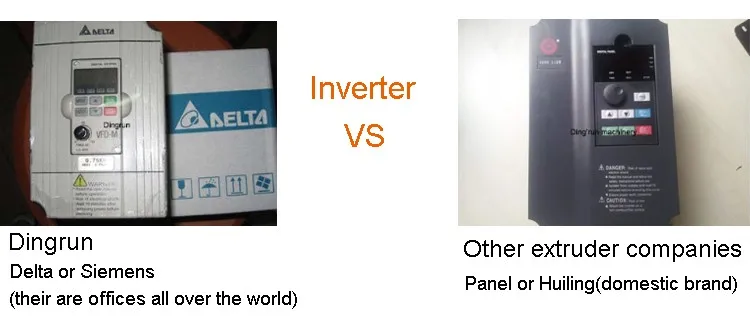

e. Voltage in China: Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers' Local voltage according to different countries

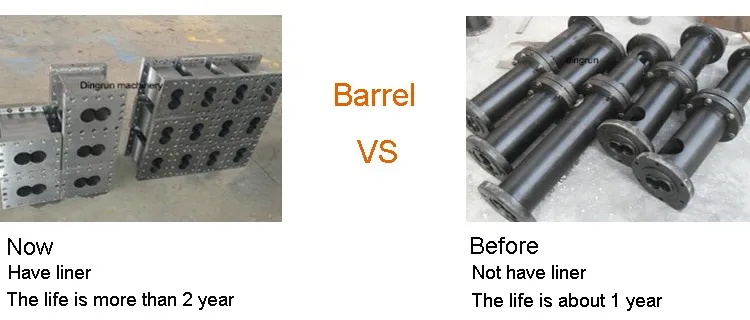

f. Machines Materials: All the artificial rice machine are made by stainless steel, this line is with reasonable design and with high automation; the screws are made by alloy steel, with building block system structure and self-cleaning function.

2.Model and Parameter of artificial Rice Machine:

Model | Installed power | Actual Consumption | Main Power | Output | Dimension |

SLG65 | 34kw | 28kw | 22kw | 100-150kg/h | 2400*1200*1800 |

SLG70 | 42kw | 30kw | 30kw | 160-200kg/h | 2600*1200*1800 |

SLG75 | 85kw | 60kw | 55kw | 300-360kg/h | 2600*1200*1900 |

SLG85 | 92kw | 75kw | 75kw | 400-500kg/h | 4500*1600*2000 |

SLG90 | 135kw | 91kw | 75kw | 800-900kg/h | 4500*2000*2000 |

3. Our advantage

4.Our Service

1)Provide factory layout according to your factory size in advance;

2)Provide the basic formula;

3)Inspect the machine before leaving the factory;Oversea installation and commissioning equipment;

4)Technician will work with your workers together and teach your workers how to install machines,

how to operate machines, how to maintain machines during daily working;

5)Our engineers will teach your workers how to clean the extruder, how to change the screw,

how to change barrel etc, and provide technology support with you forever;

6)Provide English Version of Installation / Operation / Service / Maintenance Manual.

5. Our Company