Intelligent artificial rice machine equipment

Intelligent artificial rice equipment

The New Favorite of Modern Life

With the continuous progress of technology and the improvement of people's quality of life, various intelligent devices are constantly emerging, including equipment for producing artificial rice. These equipment utilize modern technology and mechanical equipment, using beans, grains, roots, and various nutritional factors as raw materials, to produce delicious artificial rice through a series of technological processes. This article will introduce the main characteristics, working principles, and application prospects of artificial rice making equipment.

main features

Intelligent automation: Artificial rice equipment has the characteristics of high intelligence and automation, which can achieve automatic control of various process flows and intelligent production lines.

Versatility: Artificial rice equipment can process and produce a variety of artificial rice with different tastes, flavors, and contents according to different product requirements.

Various types of artificial rice

Energy conservation and environmental protection: Artificial rice equipment adopts modern technology and equipment, which has the advantages of high efficiency, energy conservation, environmental protection and hygiene, and is in line with the development trend of modern production and consumption.

Convenient and easy to operate: The artificial rice equipment has a compact structure and is easy to operate. Operators only need to be familiar with a small amount of technical knowledge to operate and maintain, making it easy to promote and apply.

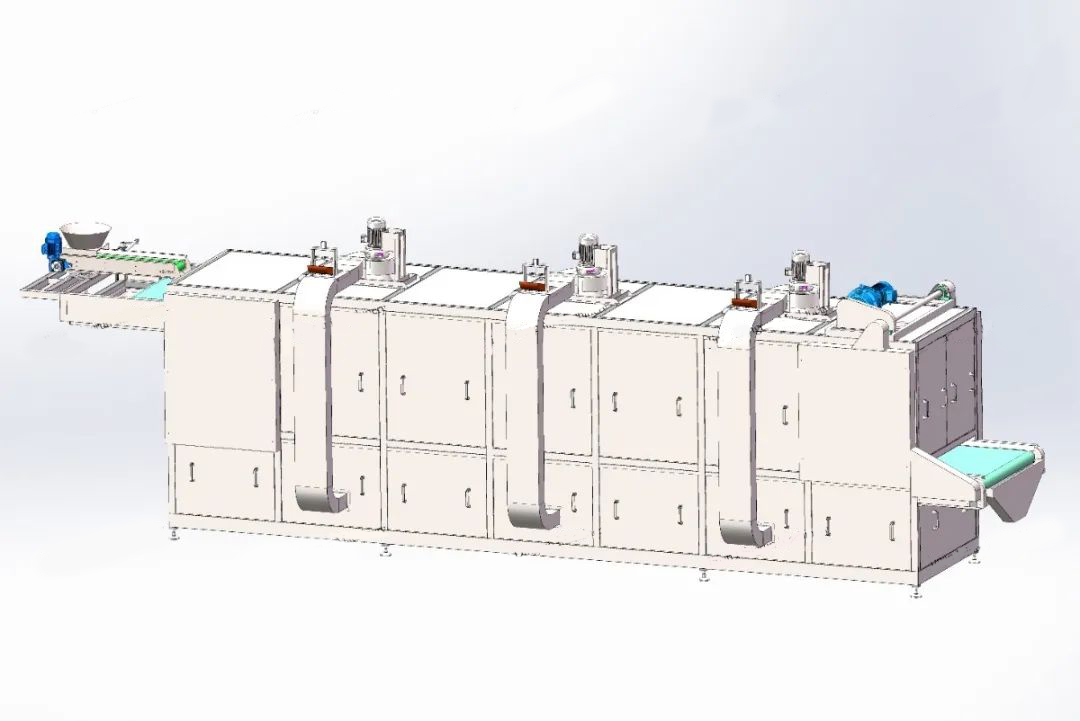

Artificial Rice Production Line - Working Principles

Artificial rice production adopts twin screw extrusion technology, which is composed of a feeding system, extrusion system, rotary cutting system, heating system, transmission system, and control system. Adopting screw extrusion technology, the material is matured and expanded into shape using high temperature and pressure, which can be completed in one go.

1. Raw material processing: Granular raw materials are processed to a certain fineness through a crushing system

2. Powder mixer: Rice noodles is mixed with some additives alone or partially, and a certain amount of water is added to fully mix evenly.

3. Feeding machine: Using a motor as the power for spiral conveying, the mixed raw materials are transported to the feeding hopper of the extruder, ensuring convenient and fast feeding.

4. Extruder: In a high-pressure environment, rice particles are extruded, and different shapes of rice particles can be produced by adjusting the process and changing the mold.

Artificial Rice Production Line - Working Principles

5. Shaker screen: The extruded particles contain a little temperature and viscosity, and are spread out through the shaker screen to avoid sticking together.

6. Air blower: Transport the product to the oven, and the height of the elevator is determined based on the oven.

7. Multi layer oven: Most ovens are electric ovens, with temperatures adjustable between 0-200 degrees Celsius through a control cabinet. The interior is made of stainless steel double layer mesh bags, and the baking time can be adjusted according to the speed, reducing particle moisture and increasing shelf life;

8. Cooling conveyor: The dried particles contain a certain temperature and are cooled to room temperature to ensure packaging quality.

Artificial rice nutrition scene

Artificial rice equipment has important application prospects in modern production and consumption. It can not only meet people's needs for nutrition, health, and delicacy, but also bring new opportunities for agricultural production, improve the added value of agricultural products and market competitiveness. In addition, with the continuous development and improvement of artificial rice technology, artificial rice equipment will also have broader application prospects and become a new favorite in modern life.

In short, intelligent artificial rice equipment has become an important driving force and support for modern production and consumption due to its highly intelligent, multifunctional, energy-saving, environmentally friendly, and convenient operation. I believe that with the progress and innovation of technology, the application prospects of artificial rice equipment will become increasingly broad, bringing more surprises and convenience to the improvement of people's quality of life.