Production process of extruded snack food

Production process of extruded snack food

The secondary extrusion technology is a common food production process, which is mainly used in the production of various puffed foods, such as edible puffed potato chips, Prawn cracker chips, squid rolls, puffed pea crisp, etc. The principle is to destroy starch particles under high temperature and pressure, allowing food to expand rapidly. Below is a brief introduction to the specific process flow of secondary extrusion and expansion.

technological process

1、 Preparation of raw materials

Firstly, it is necessary to choose high-quality raw materials. Generally speaking, common raw materials include corn starch, potato starch, tapioca, etc. In addition, an appropriate amount of seasoning and pigments can be added as needed, and water can be added to mix according to a certain proportion.

2、 One extrusion

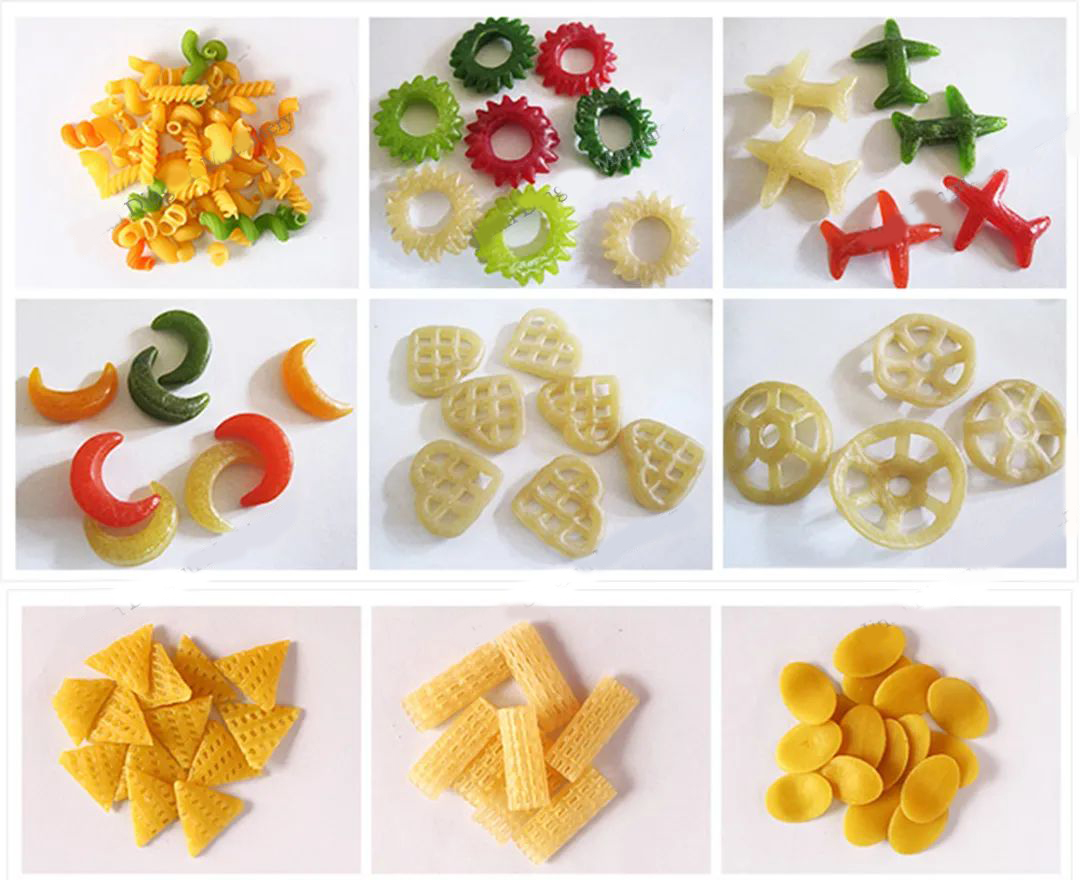

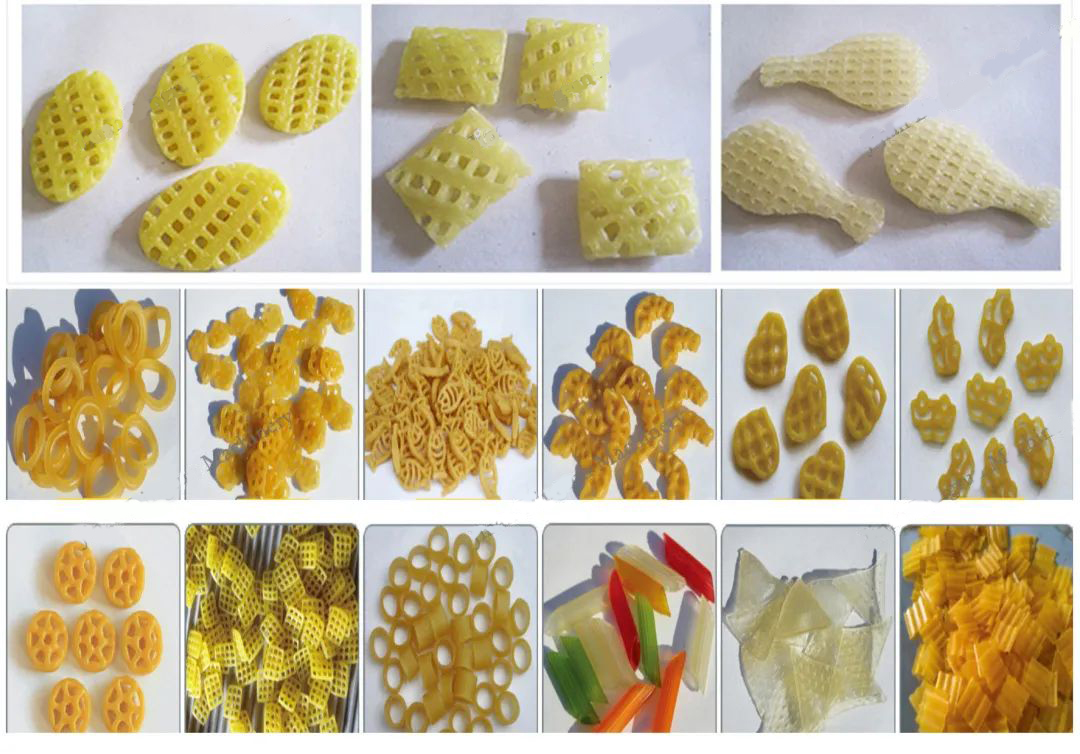

Add the stirred and mixed raw materials to the extruder and extrude them under high temperature and pressure. At this point, the raw materials will be squeezed into regular shapes, such as circles, squares, etc. At the same time, due to the action of high temperature and pressure, starch particles will rupture, which is conducive to subsequent expansion.

3、 Secondary extrusion

Add the processed material to the secondary extruder for re extrusion. At this point, the material will be squeezed into small particles and rapidly expand under high temperature and pressure.

4、 Forming, curling

According to the requirements of the product, puffed food can be further formed or curled.

5、 Drying system

After reshaping, the product is sent to the drying system through conveying equipment to stabilize the product. Low temperature drying is used to dry excess moisture, ensuring the shape and quality of the product.

6、 Screening

Sieve according to the product and retain excess leftover materials from the finished product.

7、 Fried in oil

After screening, the product enters the frying system

8、 Seasoning, packaging

And finally, puffed food can be seasoned and packaged to produce finished products.

In short, secondary extrusion technology is an important food production process, and its products have characteristics such as crisp taste, bright color, and rich nutrition. In practical operation, it is necessary to pay attention to controlling the extrusion temperature and pressure to ensure product quality and high yield.

Company :

Address :

Phone :

Email :

Skype :

Whatapp/Wechat: