floating fish feed extruder plant fish food machinery

- +86 15216413539

- We provide overseas installation service

- L/C,D/A,D/P,T/T,Western Union,Money Gram payments for offline orders.

- 100-5000kg/h

1.Certification: CE ISO SGS.

2.Motor:Siemens, ABB or Chinese Brand.

3.Formula: Free to buyers.

4.Advantage: Professional engineer team,steady quality,customization service.

5.Energy Source: Electricity,Diesel Oil, Gas.

6.After-sales Service Provided: Free spare parts, Field installation,Commissioning and training, Field maintenance and repair service, Video technical support, Online support.

Fish feed machine is suitable to make dry and wet type fish food pellet (catfish, aquarium, Tilapia, Freshwater fish and tropical fish etc.)

The final fish food shapes and sizes can be various by changing the mould.

You can get various size of fish feed from 0.8-14mm and various shapes of pet food, such as: rings, triangle, core filling pet food etc.

We not only have the basic fish feed formula , but also the professional formula based on different kinds of fish.

The advantages of extruded feed:

(1). After the feed material is puffed, the flavor is increased, the palatability is improved, and the appetite of the animal can be stimulated.

(2). Reduce the content of bacteria, mold and fungi in raw materials, improve the hygienic quality of feed, and reduce the risk of animal disease.

(3). Improve the gelatinization degree of starch, produce modified starch, improve the stability of fat, and improve the digestibility and utilization rate of feed.

(4). It can be made into various kinds of puffing feeds with various settling speeds, such as floating, slow and sinking, to meet the different living habits of aquatic animals, reduce feed loss and avoid water pollution.

(5). The expanded feed has a low moisture content and is convenient for long-term storage.

(6). Some young animals with poorly digested organs or short-feathered animal animals with digestive system can use puffed feed that is easily digested and absorbed.

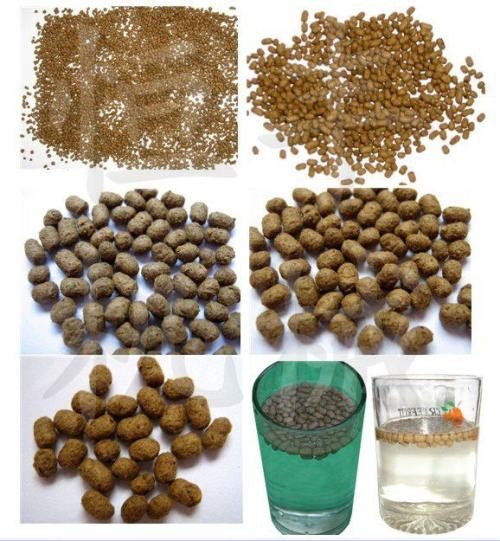

Fish feed samples:

Fish feed processing line:

mixer→screw conveyor→twin screw extruder→air conveyor→dryer→hoister→flavoring drum and oil sprayer→cooling machine→packing machine

Technical parameters:

| Model | Installed Power (kw) | Power Consumption (kw) | Capacity (kg/h) | Dimension (m) |

| DSE65 | 74 | 52 | 100-150 | 17*1.2*2.2 |

| DSE70 | 95 | 70 | 200-250 | 20*1.5*2.2 |

| DSE75 | 110 | 82 | 250-400 | 26*1.5*2.2 |

| DSE85 | 139 | 104 | 400-800 | 28*3.5*4.3 |

| DSE90 | 132 | 75 | 800-1200 | 28*3.5*4.3 |

| DSE95 | 165 | 90 | 1500-2000 | 35*3.5*4.3 |

| DSE120 | 469 | 380 | 2000-2500 | 45*20*22 |

| DSE135 | 712 | 570 | 3000-4000 | 50*20*25 |

Our service:

1)Provide factory layout according to your factory size in advance;

2)Provide the basic formula;

3)Inspect the machine before leaving the factory;Oversea installation and commissioning equipment;

4)Technician will work with your workers together and teach your workers how to install machines,

how to operate machines, how to maintain machines during daily working;

5)Our engineers will teach your workers how to clean the extruder, how to change the screw,

how to change barrel etc, and provide technology support with you forever;

6)Provide English Version of Installation / Operation / Service / Maintenance Manual.

Our customers:

Our customer factory:

Packing and delivery:

• Inside package is plastic film, outside is wooden or plywood case(based on the customers' need).

• Only plastic film nude packing with wooden pallet.

• Shipping, train, express or upon clients' demands.

Bright company certificates: