sinking fish feed pellet processing machine

- +86 15216413539

- We provide overseas installation service

- L/C,D/A,D/P,T/T,Western Union,Money Gram payments for offline orders.

- 100-5000kg/h

1.Certification: CE ISO SGS.

2.Motor:Siemens, ABB or Chinese Brand.

3.Formula: Free to buyers.

4.Advantage: Professional engineer team,steady quality,customization service.

5.Energy Source: Electricity,Diesel Oil, Gas.

6.After-sales Service Provided: Free spare parts, Field installation,Commissioning and training, Field maintenance and repair service, Video technical support, Online support.

sinking fish feed pellet processing machine

1.Product Description

Fish feed machine is suitable to make dry and wet type fish food pellet (catfish, aquarium, Tilapia, Freshwater fish and tropical fish etc.)

1). All fish food equipments are made of stainless steel.

2). The fish food whole line fully continuous and automatic.

3). The final fish food shapes and sizes can be various by changing the mould.

4). Supply different size mould free of charge.

5). We have different capacity production line for customer choose: 100-150kg/h; 200-250kg/h; 500kg/h; 1000-1200kg/h; 2 ton/h and 5 ton/h

Machine parameters:

| Model | Installed Power(kw) | Power Consumption(kw) | Capacity (kg/h) | Dimension (m) |

| 65 Processing line | 74 | 52 | 120-180 | 17*1.2*2.2 |

| 70 Processing line | 95 | 70 | 200-300 | 20*1.5*2.2 |

| 75 Processing line | 110 | 82 | 250-400 | 26*1.5*2.2 |

| 85 Processing line | 139 | 104 | 400-800 | 28*3.5*4.3 |

| 90 Processing line | 132 | 75 | 800-1200 | 28*3.5*4.3 |

| 95 Processing line | 165 | 90 | 1500-2000 | 35*3.5*4.3 |

| 120 Processing line | 469 | 380 | 2000-2500 | 45*20*22 |

| 135 Processing line | 712 | 570 | 3000-3500 | 50*20*25 |

Raw material:

Rice flour, corn flour, wheat flour, low temperature soya flakes meal, rice bran , wheat bran, fish powder, bone powder etc.

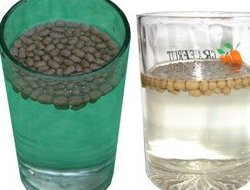

Samples of fish food:

Different capacity extruder:

2.Our advantades:

3.Service

1)Provide factory layout according to your factory size in advance;

2)Provide the basic formula;

3)Inspect the machine before leaving the factory;Oversea installation and commissioning equipment;

4)Technician will work with your workers together and teach your workers how to install machines,

how to operate machines, how to maintain machines during daily working;

5)Our engineers will teach your workers how to clean the extruder, how to change the screw,

how to change barrel etc, and provide technology support with you forever;

6)Provide English Version of Installation / Operation / Service / Maintenance Manual.

4.Customers

5.FAQ

Q: Are you a trade company or a manufacturer?

A: we are a manufacturer, welcome to visit and check the machine to my factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 20-35 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: 30% T/T in advance ,balance before shippment.

Q: How about the after-service?

A: We will send 1 engineer to the buyer's factory for a 10-day period installation and training to the operators.

Q:do you supply any formula to buyer?

A:yes, we supply formula to buyer.

6.Contact us

Tel:+86-15216413539

Skype:+8615216413539

Mobile/Whatsapp/Wechat: +8615216413539

Email:kate@brtbrightmachine.com

Jinan Bright Machinery CO.,LTD

Address:Wande Industry Park,Jinan City, Shandong Province,China